Dec 28.2023

Background

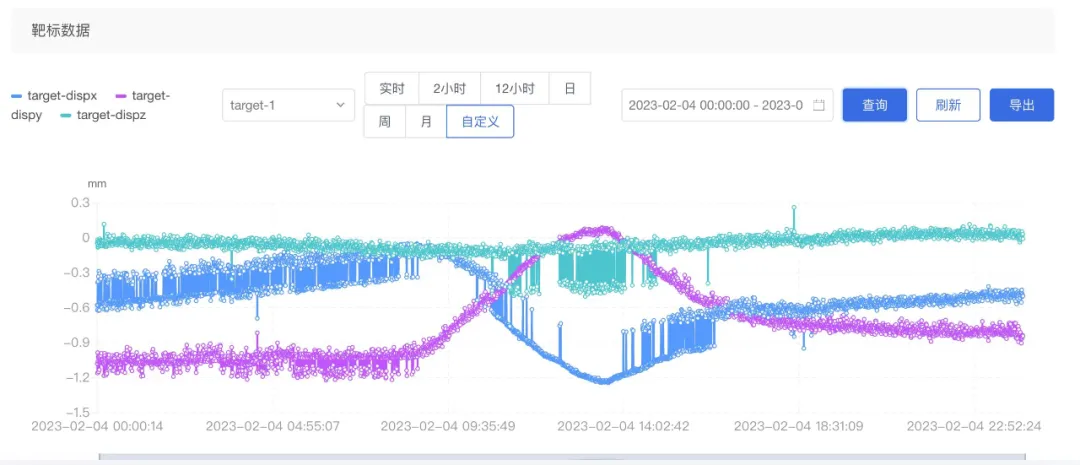

Modern engineering projects utilize various types of seismic isolation bearings, including natural rubber bearings, lead-rubber bearings, high-damping rubber bearings, elastic sliding bearings, friction pendulum bearings, and others. Post-installation, these bearings are subject to creep and temperature-induced deformations, making deformation monitoring a critical challenge. While multiple monitoring methods exist, selecting the optimal approach is essential for effective assessment. Visual monitoring systems, with their proven maturity and efficacy, offer a robust solution for projects requiring seismic isolation. Notably, RUHR IoT’s Visual Deformation Monitoring Technology has been successfully applied in building seismic bearing systems.

Location: Yuxi, Yunnan Province, China

Scope: Five monitoring devices installed in the seismic isolation layer, positioned at the four corners and center of the building.

System Configuration:

Visual Deformation Monitoring System Components

RUHR IoT’s Bearing Displacement Visual Monitoring System employs:

On-site Deployment of Visual Monitoring Equipment

RUHR IoT’s Visual Deformation Monitoring Technology delivers real-time safety monitoring for building seismic bearings, enabling early detection of structural risks. By safeguarding infrastructure integrity, we protect both building safety and human lives.

7×24小時(shí)服務(wù)熱線

公司地址

杭州市余杭區(qū)五常街道綺頤弄53號(hào)魯爾物聯(lián)總部園區(qū)

關(guān)注魯爾物聯(lián)

魯爾物聯(lián)

關(guān)注公眾號(hào)

RUHRloT